Corporate History

1950s

| 1953 | Toho Titanium Co., Ltd. was jointly established by Nippon Mining Co., Ltd. (currently JX Nippon Mining & Metals Corporation), a major copper smelting company, Kojiro Ishizuka, the founder of Osaka Special Steel Manufacturing Co. (currently Osaka Titanium Technologies Co., Ltd.), and his son Hiroshi Ishizuka, both of whom were engineers who excelled in titanium smelting, and Daiichi Bussan Corporation (currently Mitsui & Co., Ltd.), which focused on the potential of titanium. |

|---|---|

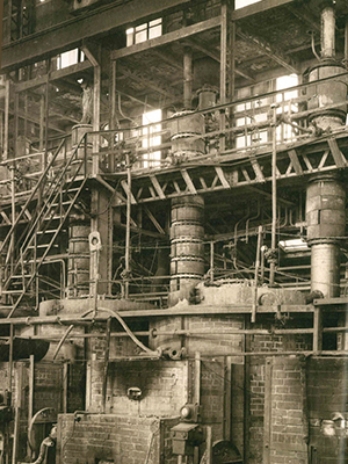

| 1954 | Constructed a plant in Chigasaki City, Kanagawa Prefecture. Production of titanium sponge at the 1st plant (facility capacity: 240 tons/year) started. Exporting to the United States began. |

| 1955 | Went public with over-the-counter transactions on the Tokyo Stock Exchange. |

| 1956 | Titanium sponge production capacity increased to 1,800 tons/year. |

1960s

| 1960 | The 1st melting plant started production of titanium ingots (facility capacity: 120 tons/year). |

|---|---|

| 1961 | Listed shares on the Second Section of the Tokyo Stock Exchange. |

| 1965 | Titanium sponge production capacity increased to 2,400 tons/year. Constructed a facility for manufacturing titanium trichloride catalysts (facility capacity: 36 tons/year). |

| 1966 | The titanium sponge received JIS certification. |

| 1968 | Titanium ingot production capacity increased to 1,200 tons/year. |

1970s

| 1970 | Started commercial production of high-purity titanium oxide. |

|---|---|

| 1971 | Titanium sponge production capacity increased to 5,400 tons/year. |

| 1977 | Completed the exporting of a titanium trichloride catalyst plant to China. |

1980s

| 1980 | Titanium sponge production capacity increased to 12,000 tons/year. |

|---|---|

| 1985 | Titanium ingot production capacity increased to 7,800 tons/year. |

| 1986 | Constructed a high-efficiency THC catalysts manufacturing facility. |

| 1987 | Established Toho Technical Service Co., Ltd. |

| 1989 | High-purity titanium oxide production capacity increased to 2,040 tons/year. |

1990s

| 1990 | Acquired Sankyo Diamond Industrial Co., Ltd. Concluded a convertible bond purchase agreement with TIMET in the United States. |

|---|---|

| 1993 | High-efficiency THC catalyst production capacity increased to 85 tons/year. |

| 1996 | ISO 9002 certified (manufacturing and sales of catalysts for propylene polymerization). |

| 1997 | High-purity titanium oxide production capacity increased to 2,160 tons/year. |

| 1998 | ISO 9002 certification range expanded (titanium tetrachloride, titanium sponge, titanium ingot, high-purity titanium oxide, etc.). ISO 14001 certified (all departments of Chigasaki Plant). Completed an EB ingot manufacturing facility (Hitachi Plant) (facility capacity: 2,640 tons/year). Established Toho Catalyst Kurobe Co., Ltd. |

| 1999 | ISO 9001 certification range expanded (design, development, manufacturing and sale of catalysts for propylene polymerization, titanium tetrachloride, titanium sponge, high-purity titanium, titanium ingot, high-purity titanium oxide, titanium powder, and calcination powder). Constructed an ultra-fine nickel powder manufacturing facility (facility capacity: 24 tons/year). |

2000s

| 2000 | ISO 9001 certification range expanded (design, development, manufacturing and sale of nickel powder). Toho Catalyst Kurobe Co., Ltd. changed its name to Toho Catalyst Co., Ltd. (Catalysts Business transferred to Toho Catalyst). |

|---|---|

| 2003 | Titanium sponge production capacity increased to 13,000 tons/year. Obtained JIS Q 9100 certification (design, development, manufacturing and sale of titanium sponge for aircraft). |

| 2005 | Titanium sponge production capacity increased to 15,000 tons/year. Sold Sankyo Diamond Industrial Co., Ltd. |

| 2006 | Listed on the First Section of the Tokyo Stock Exchange. |

| 2007 | Created a corporate brand logo. Titanium sponge production capacity increased to 16,000 tons/year.  |

| 2008 | Merged with Toho Catalyst Co., Ltd. Established Yahata Plant (EB ingot manufacturing) (facility capacity: 10,000 tons/year). Ingot production capacity reached 19,000 tons/year. |

| 2009 | Established Toho Titanium America Co., Ltd. Established Toho Material Co., Ltd. (a joint venture company in which Nakashima Sangyo Co., Ltd. owns 20%, Morimura Bros., Inc. 10%, and our company 70%). Established Toho Titanium Europe Co., Ltd. |

2010s

| 2010 | Titanium sponge production capacity increased to 26,400 tons/year. Wakamatsu Titanium Sponge Plant started commercial operation. |

|---|---|

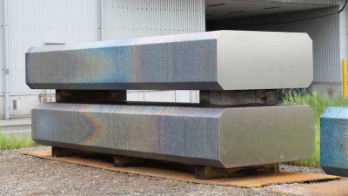

| 2011 | Started the mass production of the direct-cast titanium slab (DC Slab®). |

| 2012 | Titanium sponge production capacity increased to 28,800 tons/year. Expanded the production capacity of the Wakamatsu Titanium Sponge Plant. |

| 2013 | Acquired aircraft certification for Wakamatsu Plant’s titanium sponge. Titanium sponge production capacity increased to 25,200 tons/year (an efficient production system was established in the Chigasaki Plant). |

| 2014 | Established the second EB melting furnace at the Yahata Plant. Invested in Nippon Steel & Sumikin Naoetsu Titanium Co., Ltd. (currently Nippon Steel Naoetsu Titanium Co., Ltd.). (After our investment, Nippon Steel & Sumitomo Metal Corporation (currently Nippon Steel Corporation) owns 66% and our company 34%). |

| 2016 | Established a joint venture company named Advanced Metal Industries Cluster and Toho Titanium Metal Company Limited (Advanced Metal Industries Cluster Company Limited invested in 65% and Toho Titanium 35%) in the Kingdom of Saudi Arabia. |

| 2017 | Completed the construction of a titanium sponge manufacturing plant in the Kingdom of Saudi Arabia. |

| 2019 | Started the operation of the titanium sponge Joint Venture manufacturing plant in the Kingdom of Saudi Arabia. |

2020s

| 2020 | Established TOHO WORLD Corporation. Relocated the headquarters to Yokohama City, Kanagawa Prefecture. |

|---|---|

| 2021 | Completed the new Wakamatsu Plant for nickel powder (4th plant). |

| 2022 | Designated for Prime Market, Tokyo Stock Exchange. |