Catalysts Business

THC catalyst highly evaluated by PO manufacturers

for its performance and quality

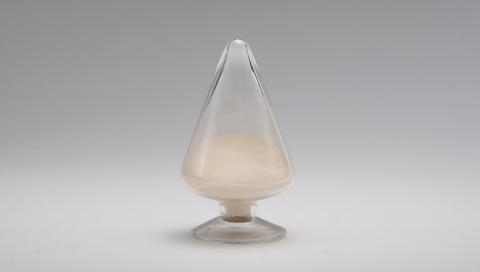

Leveraging the ability to procure titanium tetrachloride and magnesium chloride in-house, we develop, manufacture (including toll manufacturing), and sell catalysts for the production of general-purpose plastics such as polypropylene (PP) and polyethylene (PE), and other polyolefin (PO) such as polybutene-1 (PB-1) and polyolefin elastomer (POE). We also produce and sell magnesium chloride for raw materials for catalysts, pharmaceutical intermediates, and other applications.

Our main product “THC catalyst” has been garnering immense praise from PO manufacturers for its performance and stability of quality.

01THC catalyst with the world’s highest-level performance

THC catalyst* is a MgTi (magnesium-titanium)-based high performance catalyst unique to our company, which is used in the polymerization of olefin monomer into polyolefin. In response to increasing expectations for improved mechanical properties and processability of polypropylene year by year, the catalysts have been playing an important role in the industry.

Requirements for catalyst characteristics vary depending on polypropylene processes, such as gas, bulk and slurry, and grade of polypropylene produced. However, we produce various types of THC catalysts to meet a wide range of market demand. In addition to propylene, our catalysts are applicable for the polymerization of other olefins such as ethylene and 1-butene, etc.

We strive to optimize product quality to satisfy individual needs of customers to support them achieve their maximum performance. We also strive to realize world highest level of performance through continuous product improvement and the pursuit of production technologies.

*“THC” stands for Toho High efficiency Catalyst. It has been widely used across the world since commercial production started in 1986.

02Environmentally friendly polyolefin

Polyolefin is used in everyday fields that are essential to daily life, such as the interior and exterior designs of automobiles, home appliances, sanitary products, packaging materials, food containers and more. Polyolefin is a material that contributes to an affluent and sustainable society from the viewpoints of material weight reduction, processability, and recyclability.

03Enhancing added value of polyolefin

THC catalyst is an unrivaled catalyst for olefin polymerization developed by making full use of physical property design and preparation technology for the pore structure and particle size distribution control of the polymer support. It is also manufactured by utilizing chemical immobilization technologies for active species and electron donors, which are important for achieving polymerization activity and stereoregular control. It provides the world’s highest level of performance and added value, especially for high-rigidity and high-impact PP grades used in automobile bumper materials.

In addition, its high polymerization activity improves cost performance in general-purpose PP grade production. The technologies developed here have been applied to other PO catalysts such as for PE, PB-1, POE, etc.

04THC production system

The catalyst production team works to achieve a high level of operational excellence through safety and environmental considerations as well as production efficiency. In FY 2010, we received the TPM*1 Advanced Special Award*2 from the Japan Institute of Plant Maintenance for its plant maintenance technology accumulated over many years, outstanding process control technology, high stability of quality, and high cost-competitiveness.

*1 TPM: Total Productive Maintenance

*2 Advanced Special Award: Intended for commending business entities that set important goals for the development of TPM activities and have achieved superior results.

Kurobe Plant, which manufactures THC catalysts

Kurobe Plant, which manufactures THC catalysts

05Catalyst-related products

Catalyst for PO production

THC-C

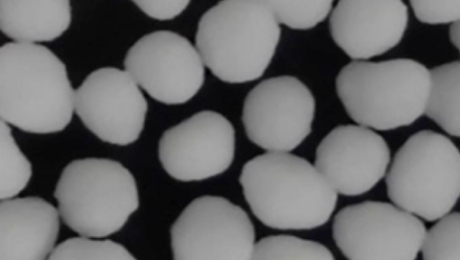

It is the generic name for our spherical catalysts. It has excellent process operability and is widely used in PP manufacturing processes, especially gas and bulk processes. Because of its porous catalyst structure, it is suitable for the manufacturing of high value-added PP products such as high-rubber ICP products. Having developed our catalysts with 30-40% higher activity than conventional ones in the market, THC-C demonstrates world-leading polymerization activity with excellent stereoregularity. In addition, catalyst particle size can be tailored to the demand of various polyolefin manufacturing processes.

PP powder obtained by the THC catalyst

PP powder obtained by the THC catalyst

Catalyst for high stiffness PP

We have developed and commercialized highly stereospecific catalysts. It is used for PP that requires high stiffness such as automotive materials.

Catalyst for ICP (impact copolymer)

By establishing a technology for controlling the pore volume and distribution of catalysts, we have developed and commercialized porous catalysts with large particle size. It is used for impact copolymers that require a high rubber content.

Environmentally-friendly phthalate-free catalyst

Non-phthalate type catalysts are required since the phthalate used in the catalyst is listed as SVHC (Substance of Very High Concern) in the European REACH regulations. We have commercialized innovative catalysts without using phthalate, which surpasses the performance of phthalate catalysts. It is beginning to be used as an alternative to phthalate catalysts.

Catalyst for PE

Our technology developed for propylene polymerization catalysts can also be applied to ethylene polymerization catalysts.

Catalyst for PB-1

Our technology developed for propylene polymerization catalysts can also be applied to catalysts for polymerization of α-olefins, such as 1-butene and more.

Catalyst for POE

Our technology developed for propylene polymerization catalyst can also be applied to polyolefin elastomer (POE) polymerization catalysts, which are obtained by copolymerization of ethylene and α-olefin.

Customized catalyst

We can study and customize PO catalysts according to customer specific requests.

Toll manufacturing catalyst

We can manufacture PO catalysts according to the manufacturing recipe provided by a customer.

Catalyst-related products: Raw materials for catalyst support and raw materials for pharmaceutical intermediates

Magnesium chloride powder

We can provide high-purity anhydrous magnesium chloride powder as a raw material of catalyst support for olefin polymerization and as an intermediate for pharmaceuticals.

Magnesium chloride lump

We can provide high-purity anhydrous magnesium chloride also as a 300kg block shape for use as catalyst supports for olefin polymerization.

Mixture of magnesium chloride powder and titanium trichloride

A mixture of magnesium chloride powder and titanium trichloride. It is mainly used as a catalyst support for olefin polymerization. The mixing ratio can be adjusted as requested.

External donor for PP production

U-donor™ / T01-donor™

In recent years, the demand for high flow and high crystallization PP suitable for thin-walled high speed injection molding has been increasing, and importance of improving the productivity of nonwoven fabrics used in masks have been growing. U-donor™ can be used in propylene polymerization to produce high-flow PP while maintaining a high level of PP stereoregularity. In addition, the increase in the speed of PP crystallization due to the high stereoregularity is expected to reduce additives such as crystallization nucleating agent.

In addition, we have developed and commercialized T01-donor™ as an external donor with higher hydrogen responsiveness and copolymerization activity than U-donor™.

06Products other than catalyst-related ones

Aqueous solution of titanium trichloride

We produce aqueous solutions of titanium trichloride for chemical synthesis.