Strengths of Toho Titanium

Four strengths for

creating new added value

Toho Titanium develops and manufactures high value-added products based on its technologies,

and provides products that go beyond customers’ needs and expectations.

Core technologiesof Toho Titanium

- Unique technology for refining titanium

- Chlorination and reduction technologies

nurtured through titanium refining - Powder control technology

-

1Manufacturing capacity

VIEW MORE

-

Manufacturing of high-quality products at low cost, based on the technologies that have been nurtured for many years

-

2Development capacity

VIEW MORE

-

Development of new materials that can be applied to various fields, based on the knowledge accumulated through the R&D of titanium

-

3Quality control capacity

VIEW MORE

-

Quality management system based on excellent equipment and employees’ stance of pursuing quality thoroughly

-

4Flexibility

VIEW MORE

-

Flexible response with our integrated production system. Customization of products according to each client’s needs and specifications

Concrete examples

of our strengths

Manufacturing capacity

-

We manufacture products by combining the “Kroll Process” with our unique technology.

We have two titanium metal refining plants in Japan and one plant outside Japan as some of a few plants in the world. We manufacture high-purity titanium metals that allow impurity control.

-

High level operational excellence

Our team for producing catalysts is highly evaluated, for its technology that has been accumulated for many years for maintaining plants, its outstanding process control technology, the high level of quality stability, cost competitiveness, etc.

Development capacity

-

WEBTi

We contribute to the realization of a hydrogen society with porous titanium.

The porous titanium metal sheet “WEBTi”, which was developed with our unique technology, is a new material that possesses the characteristics of porous metal, including liquid permeability and conductivity, and the strong points of titanium, including corrosion resistance and strength. We assume that it will be used for electrode materials, diffusion layers, filters, etc. in a highly corrosive environment.

-

LLTO™

Power of titanium for EVs and solid-state batteries

Lanthanum lithium titanate (LLTO), which is a solid-state electrolyte composed of titanate compounds for high-performance batteries, can improve the degree of freedom in use of generated electricity. Currently, we engage in development for applying it to the batteries of electric vehicles (EVs) and the recovery of lithium from seawater.

Quality control capacity

-

High-quality titanium that can be used for aircraft

It can be used as a material for engine parts and structural materials in the aerospace industry where rigorous quality requirements need to be met. In the world, there are a few companies that can supply titanium sponge for aircraft.

-

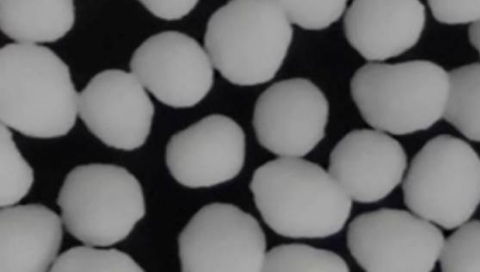

Nickel powder

Ultra-thin electrode materials for high-end MLCC

Our nickel powder can meet difficult demand for nano-level particle diameters and highly precise particle size distribution control, as a material of electrodes for multi-layer ceramic capacitors (MLCC), for which ultimate thinness is demanded.

Flexibility

-

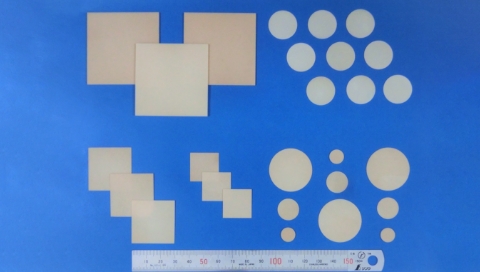

It is possible to supply titanium products of varied shapes.

We supply not only titanium sponge produced by refining titanium ore, but also square or round-shaped ingots, derivatives from titanium ingots which are produced by melting and casting titanium sponge, and billets that are microstructure-controlled by casting.

-

Environmentally-friendly customized catalysts

We have developed catalysts that do not include substances of very high concern (SVHCs) specified by REACH in Europe and have quality surpassing that of conventional ones. We also respond to the manufacture of customized catalysts according to clients’ needs.