High-Purity Titanium Oxide (Titanium Dioxide)

High-purity titanium oxide powder with a purity level of 3N or higher

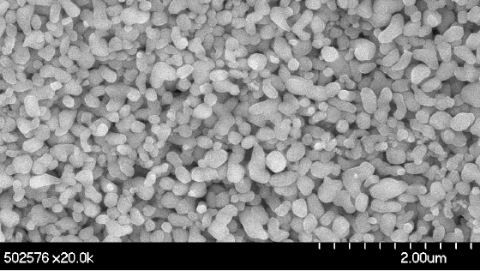

Our high-purity titanium oxide is produced by the vapor-phase oxidation method. In the method, titanium tetrachloride, a chloride of titanium, is vaporized and then oxidized with oxygen to produce titanium oxide. Our advantage is that we can produce high-purity titanium oxide at the 3N or 4N level by using high-purity titanium tetrachloride refined for titanium metal refining as a raw material.

Purposes of use

Our high-purity titanium oxide is processed into barium titanate at our customers’ sites and used in various electronic parts. Furthermore, our high-purity titanium oxide is used as additives for optical lenses, pharmaceutical products, foods, etc., given its high purity. Our high-purity titanium oxide production process is the only one that has obtained a pharmaceutical manufacturing license and a food additive manufacturing license among Japanese titanium oxide manufacturers.

-

Electronic parts

- Multi-layer ceramic capacitor (MLCC)

- PTC thermistor

- Filter

- Piezoelectric components

-

Other

- Optical

(Additives for lenses with a high refractive index) - For pharmaceuticals and foods

(For coating agents and color adjustment)

- Optical

Specs

1. For Electronic parts

(%)

| Grade | TiO2 %min. |

Al %max. |

Fe %max. |

Cl %max. |

Rutile content %min. |

Ignition loss %max. |

Specific surface area m2/g |

Average size μm |

|---|---|---|---|---|---|---|---|---|

| HT0110 | 99.9 | 0.001 | 0.001 | 0.01 | 90 | 0.08 | 1 – 2 | <10 |

| HT0210 | 99.9 | 0.002 | 0.002 | 0.01 | 90 | 0.25 | 2 – 3 | 2.10 – 2.55 |

| HT0514 | 99.9 | 0.002 | 0.002 | 0.025 | 90 | 0.25 | 6 – 7 | – |

| HT1311 | 99.9 | 0.002 | 0.002 | 0.045 | 80 | – | 8 – 14 | – |

| HT1701 | 99.9 | 0.002 | 0.002 | 0.05 | – | – | 15 – 20 | – |

| HT2321 | 99.9 | 0.001 | 0.001 | 0.13 | – | – | 20 – 27 | – |

In addition to the above, small particle size products, pherical products and other developed products are available. Please feel free to contact us for more information.

2. For pharmaceutical additives

| Grade | TiO2 %min. |

Pb ppm max. |

As2O3 ppm max. |

Water solubility mg max. |

Specific surface area m2/g |

|---|---|---|---|---|---|

| NA61 | 99.0 | 10 | 10 | 2.0 | 8 – 10 |

3. For food additives

| Grade | TiO2 %min. |

Pb μg/g max. |

As2O3 μg/g max. |

Water solubility %max. |

Ignition loss %max. |

Specific surface area m2/g |

Hydrochloric acid soluble material %max. |

|---|---|---|---|---|---|---|---|

| NA61 | 99.0 | 10 | 1.3 | 0.25 | 0.5 | 8 – 10 | 0.5 |

4. For materials to be added to glass and lens

| Grade | TiO2 %min. |

Al | Fe | Cr | Ni | Mn | Co | Cu | Rutile Content %min. |

Specific surface area m2/g |

Average size μm |

|---|---|---|---|---|---|---|---|---|---|---|---|

| ppm max. | |||||||||||

| HT0110 | 99.9% | 10 | 90 | 1 – 2 | <10 | ||||||

5. 4N products

| Grade | TiO2 %min. |

Al | Fe | Si | Sn | As | Ni | Cr | Cu | Cl | Rutile Content %min. |

Average size μm |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ppm max. | ||||||||||||

| HT0270 | 99.99 | 5 | 10 | 5 | 5 | 5 | 5 | 5 | 5 | 100 | 90 | 2.16 – 2.96 |