Porous Titanium Sheet/WEBTi®

A revolutionary new material developed by combining the most of titaniumʼs features, such as high corrosion resistance, with the most of porous metalsʼs features.

WEBTi® is porous sintered titanium that possesses such characteristics as liquid and air permeability, electrical conductivity, and high corrosion resistance, and it is applicable as electrode materials and filters which should withstand in highly corrosive environments.

To realize hydrogen society in pursuing the SDGʼs, water ele ctrolysis is increasingly needed in recent years, and WEBTi® is particularly suitable for PTL (porous transport layer) of PEM (Polymer Electrolyte Membrane or Proton Exchange Membrane) water electrolyzer or fuel cell.

-

Features of porous metal

- 1. Air/liquid permeability

- 2. Electrical/thermal conductivity

- 3. Shock absorption property

- 4. Large specific surface area

-

Features of titanium

- ・High corrosion resistance

- ・High strength

-

Porous titanium

- ・Electrodes and filters for corrosive environments

- (e.g. PEM water electrolysers PTL).

PEM water electrolyzer (Hydrogen production equipment)

WEBTi®-K

-porous titanium sheet-

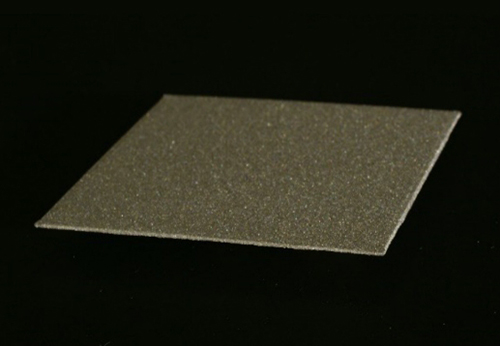

WEBTi®-K is a porous titanium metal sheet made of titanium powder paste. Its characteristics are that it is a thin sheet with superior flexibility and smoothness and has a small pore size.

Specification List

| Raw material | Titanium powder paste |

|---|---|

| Standard size | 570 × 420 mm or less *Please contact us for larger one |

| Standard thickness | 0.1 / 0.2 / 0.25 mm *Please contact us for other thickness |

| Porosity | 40% |

| Feature | High Smoothness |

| Applications | PEM water electrolysers PTL, etc. |

Appearance

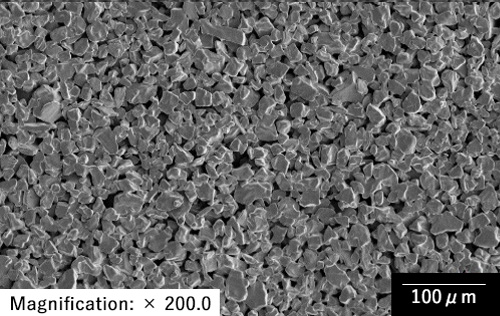

Appearance Surface (SEM)

Surface (SEM)

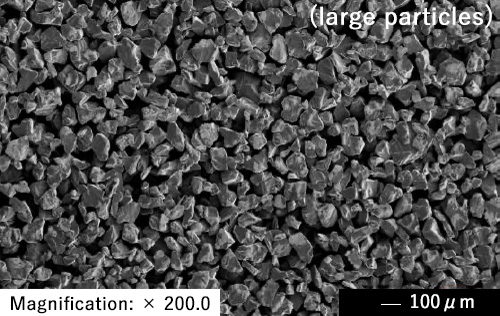

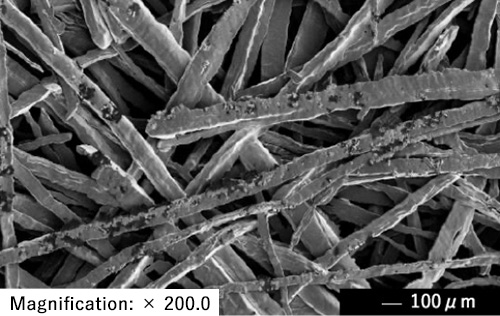

Other developed product

-porous titanium sheet-

-

T-type

-

S-type

-

F-type